Metronic HS Hybrid

OFF-COIL WIRE STRAIGHTENER

The METRONIC are automatic wire straightening machines that produce straight and cut to length bars.

WORKABLE DIAMETER RANGE

∅8 - ∅20 mm / #3 - #6

KEY FEATURES

AFS (Advance Feeding System)

Security guaranteed

Automatic tying and collection

Automatic tagging machine

A state-of-the-art drive and control system

De-coiler automation

Pre-feeding group

Automatic wire-change

Complete use of each coil, minimised waste

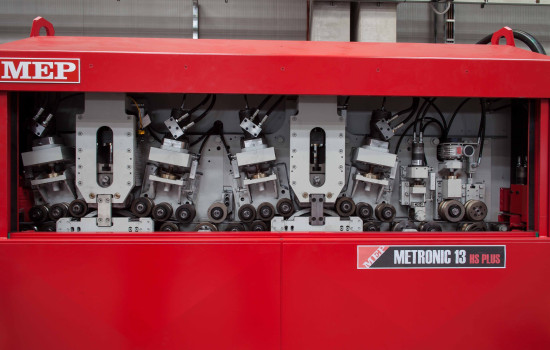

Metronic 13 HS Plus

OFF COIL WIRE STRAIGHTENER

COIL ∅5 - ∅13 mm

• AFS 3 (Advanced Feeding System) Generation III

• Single wire or two wires at the same time production

• Cut to size up to 21 m (*)

• The high speed attainable up to 9 m/s

• Portable straightening device (optional)

• Winch (optional)

• Pre-feeding group

• Extractor drive rollers

• Automatic squaring device (optional)

• Automatic tying and collection (optional)

• Automatic tagging machine (optional)

• Centralised greasing system

Request information

Metronic 16-1 HS

OFF COIL WIRE STRAIGHTENER

COIL ∅6 - ∅16 mm

• AFS 3 (Advanced Feeding System) Generation III

• Single wire or two wires at the same time production

• Cut to size up to 21 m (*)

• Portable straightening device (optional)

• Winch

• Automatic multi-wire pre-feeder

• Extractor drive rollers

• Automatic squaring device (optional)

• Automatic tying and collection (optional)

• Automatic tagging machine (optional)

• Centralised greasing system

Request information

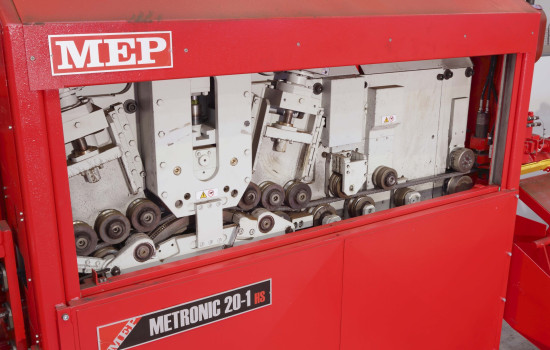

Metronic 20-1 HS

OFF COIL WIRE STRAIGHTENER

Single wire ∅8 - ∅20 mm / #3 - #6

• AFS 3 (Advanced Feeding System) Generation III

• Single wire or two wires at the same time production

• Cut to size up to 21 m (*)

• Motorized pre-driving group with winch and portable straightening

• Automatic multi-wire pre-feeder

• Extractor drive rollers

• Automatic squaring device (optional)

• Automatic tying and collection (optional)

• Automatic tagging machine (optional)

• Centralised greasing system

Request information