WRR

The modular design and the high level of automation available in the various versions, are able to satisfy the most diverse production needs, managing the production of the bars ‘cut to length’ in a completely automatic way. The work cycle can be managed entirely by the automation (optional) which is able to optimise the various elements that make up the system, whether they are intermediate collection units (buffers) or collection of the bars produced, as well as in cases where one or more automatic tying units are present.

WRR

𝐖𝐑𝐑

The modular design and the high level of automation available in the various versions, are able to satisfy the most diverse production needs, managing the production of the bars ‘cut to length’ in a completely automatic way. The work cycle can be managed entirely by the automation (optional) which is able to optimise the various elements that make up the system, whether they are intermediate collection units (buffers) or collection of the bars produced, as well as in cases where one or more automatic tying units are present.

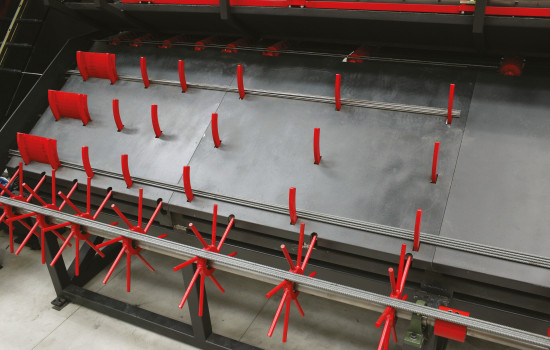

𝐃𝐨𝐮𝐛𝐥𝐞 𝐟𝐥𝐲𝐢𝐧𝐠 𝐬𝐡𝐞𝐚𝐫𝐬 𝐰𝐢𝐭𝐡 𝐥𝐨𝐧𝐠𝐢𝐭𝐮𝐝𝐢𝐧𝐚𝐥 𝐦𝐨𝐯𝐞𝐦𝐞𝐧𝐭

The WRR 16 D - WRR 20 D use a cutting system whose technology is based on 2 independent flying shears that act through a longitudinal movement synchronised with the feed speed of the 2 single wire rods. This ensures a precise cut of the 2 wires being worked in compliance with the required measurement tolerances.