CS

AUTOMATIC SHAPING MACHINERY

The CS shaping plant is an automatic solution for the production of stirrups and shapes.

Flexibility:

It processes bars from 8 to 50 mm in diameter and produces elements up to 18 m long.

High productivity:

Versions with 2 moving heads ("2M") and high-performance bending machines.

Accuracy:

Central clamp for maximum precision and scrap reduction.

Advanced control:

Drive and control system for automation, productivity and flexibility.

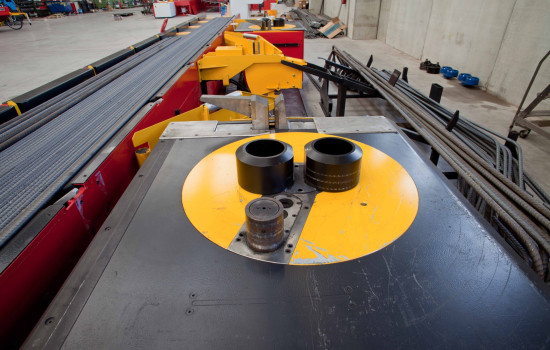

Fast pins change:

Production of bends with variable radius.

Ergonomics and safety:

Automatic design and functions to reduce effort and risk.

Automatic evacuation system:

Finished products in special racks.

Advantages:

Reducing costs, increasing productivity, better quality, flexibility, safety.

Options:

Software work management, automatic lubrication, customised accessories.

Ideal for the production of stirrups and shapes in a variety of industries.

CS 40 SX

AUTOMATIC SHAPING MACHINERY

BARS ∅10 - ∅40 mm (#3 - #11)

• Automatic shaping.

• Suitable for both series production and single processing (single wire up to 50 mm).

• Automatic complex bends.

• Large radius pins.

• Suitable for a variety of production requirements with multiple configurations and layouts.

• Perfect integration with LTM, CUT LINE, FLEXIPLUS, SUPERFLEX and straightening systems METRONIC.

• Ideal for large stirrups and shapes with a small number of bends.

• It allows bidirectional bending on the same bar.

• Reduces set-up times and scrap with patented devices.

• Advanced control for automation.

Request information

CS 440SX / CS 440 2M

AUTOMATIC SHAPING MACHINERY

BARS ∅10 - ∅40 mm (#3 - #11)

Automatic shaping.

Suitable for both series production and processing of individual elements, with "2M" versions for maximum productivity thanks to the simultaneous operation of 2 bending heads.

It performs clockwise and counterclockwise bends up to ± 180° on both sides of the shaped part, reducing costs and increasing flexibility.

Suitable for medium and large stirrups with one or more bends on both sides, thanks to a complete range of accessories.

Can be integrated with other cutting systems and automatic straighteners, with dynamic workflow management by advanced automation (optional).

Different machine configurations are available: with two movable bending units ("2M") or with one fixed and one movable bending unit (SX).

It allows bidirectional bending on the same bar fully automatically.

CS 440 and CS 460 make mouldings with multiple clockwise and anticlockwise bends up to ± 180° on both ends.

The CS 440 2M and CS 460 2M guarantee maximum precision through the use of a central clamp that locks and supports the bars during machining.

CS 460 2M

AUTOMATIC SHAPING

BARS

∅45 mm / #14

∅10 mm / #3

High-performance bar bending up to ±180º

Large radii pins

Rapid bar alignment

There are three different configurations of the machine: with two mobile bending units or with one fixed and one mobile bending unit.