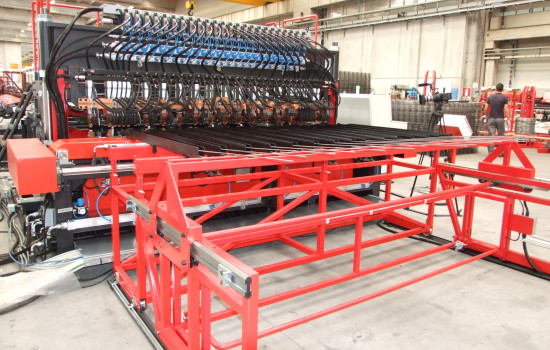

MRSA

MESH WELDING PLANTS FROM PRE-CUT LENGTHS

Flexibility, productivity, and sturdiness are the hallmarks of the MRSA series plants, designed for the production of welded mesh from pre-cut bars,off-coils, or a combination of both, either cold drawn or hot rolled.

Adaptability to different needs:

• Standard or custom mesh: Ideal for the production of mesh with constant or variable diameters and pitches, meeting a wide range of production needs.

• Wide range of diameters: They work with wire from 4 to 25 mm in diameter.

Complete automation:

• They reduce manual operator intervention thanks to an automated production process.

Cost optimization:

• They allow to reduce industrial costs per ton thanks to the use of a smaller number of machines and operators.

Custom solutions:

• They offer multiple configurations to adapt to the specific production and layout needs of the customer.

• The use of standard modular technologies allows to create a "tailor-made" plant.

Device and accessory combinations:

• The MRSA series allows the integration of a wide range of devices and accessories to further optimize the production process.

The MRSA series plants represent a versatile, efficient, and robust solution for the production of high-quality welded mesh.

MRSA M

MRSA M (Manual)

MESH WELDING PLANT FROM PRE-CUT LENGTHS

Manual longitudinal bar loading.

Automatic transverse bar feeder.

Automatic panel ejector.

Bridge welding.

MRSA S

MRSA S (Semi-automatic)

MESH WELDING PLANT FROM PRE-CUT LENGTHS

Semi-automatic longitudinal bar loader: An efficient and safe process.

Automatic transverse bar feeder: Efficient solution for continuous production.

Unloading carriage: For the automatic removal of produced panels.

Stacker: For the automatic stacking of finished panels.

Bridge welding: Ensures uniform weld quality.

MRSA JT

MRSA JT (Just in Time)

MESH WELDING PLANT FROM PRE-CUT LENGTHS

• Coil feeding: both longitudinal and cross wires fed from coils.

• Rapid mesh size change: automatic and quick mesh size adjustments.

• Multiple wire coils: automatic coil switching for different wire diameters.

• Automatic straightening: two automatic straightening machines for longitudinal and cross wires.

• Automatic cutting and insertion: bars cut and inserted as needed.

• Versatile welding: cross wires can be welded above or below longitudinal wires.

• Automated process: automatic panel collection and evacuation.

• Uniform welding: multiple transformers for even current distribution.

Request information

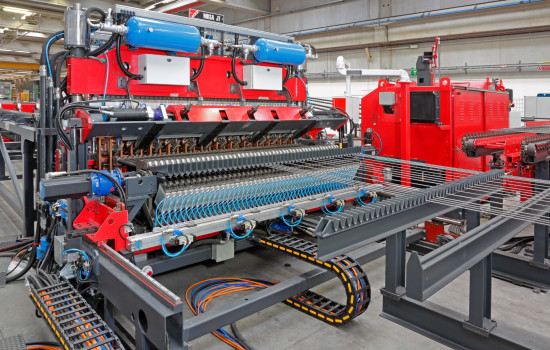

MRSA F

MRSA F (Force)

MESH WELDING PLANT FROM PRE-CUT LENGTHS

Feeding: pre-straightened and pre-cut bars for both longitudinal and cross wires.

High welding force: hydraulic cylinders enable welding of thicker bars (Ø16 mm for both longitudinal and cross wires).

Welding up to Ø25 mm: maximum technological expression for customized meshes of medium and large dimensions.

Uniform welding: one transformer per welding cylinder ensures consistent electrical current at each welding point.

Positioning flexibility: rapid cylinder movement via automatic robot or manual operation.

Automatic insertion: automatic insertion of cross wires, mesh forming, collection, and discharge.

Suitable for structural meshes: ideal for producing complex structural meshes.

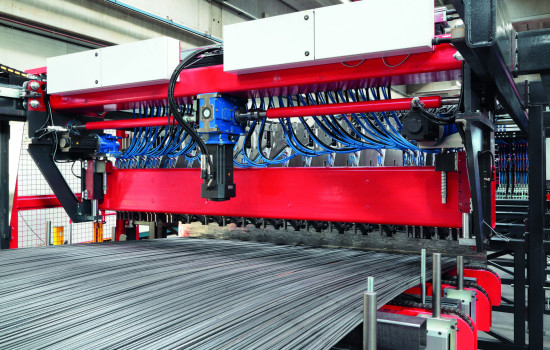

MRSA CL HA

MRSA CL HA (CL+Up and down)

MESH WELDING PLANT FROM PRE-CUT LENGTHS

Hybrid feeding system: pre-cut and pre-straightened longitudinal bars; transverse wire from coil (cold-drawn or hot-rolled, smooth or ribbed). This feeding combination is also called "hybrid".

Versatile welding: cross wires can be welded above or below longitudinal bars without turner stacker device (automatic device for the sequential rotation and stacking produced mesh panels).

Automated processes: automatic straightening, cutting, insertion of cross wires, mesh forming, and panel evacuation.

Flexible longitudinal bar insertion: semi or fully automatic based on customer needs.

Even current distribution: multiple transformers adjusted to mesh width for consistent welding.

Pneumatic welding: welding unit powered by pneumatic cylinders.